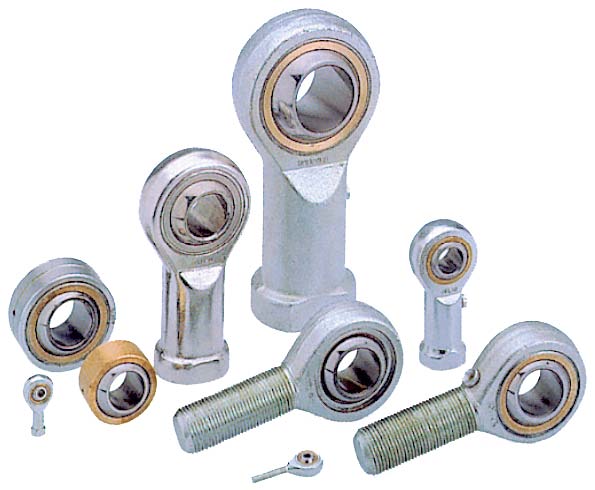

Rod ends and spherical bearings are a space-saving mechanical unit intended as the transmission of oscillating movements combined with rotation and level control.

RODOBAL rod ends and spherical bearings typical uses are in

construction of machine tools, automatic machines, packaging machines, textile machinery, food machinery, pneumatic automation and many more industrial mechanical fields.

RODOBAL’s manufacturing program includes a wide range of different grades of steel,

surface treatment, surface finish, design, lubrication and thread selection. This is to achieve the optimal choice for different use cases. When selecting link heads and link bearings, the design determines which design to choose. For example, for small loads and movements where lubrication-free design is desired, the economical type RF/RM (internal or external thread) …-AE is advantageously chosen. See cheat sheet below to make it easier to choose the type and design.

The type “Heavy Duty” is available in rust-resistant, stainless or acid-resistant design. Depending on what the rod end/spherical bearing will be exposed to, we combine the structure to the “right” composition. The greaseable types can be equipped with stainless steel bearing instead of standard, bronze bearing. The inner ring (ball) is available in hard chromed design, which has an advantage in corrosive environment. A common size and type for eg motor sports is RM… -SE ICR x 1.5. RM external thread. –SE Heavy Duty, lubrication-free. ICR hard chromed inner ring x 1.5 fine thread. For extened life span, the rod ends are supplemented with our seal with stainless steel spacers, type RERS.

| Pneumatics, small loads, hand operated such as lever controls etc. | “Standard” type…. AE (lubrication-free) “Basic” type…. (greasable) |

| Higher dynamic loads and vibrations | “Heavy Duty” type…SE (lubrication-free) or… S (lubrication-free) |

| Extreme loads and dynamic stress from jerks and vibrations | “Extra Heavy Duty” type…XE (lubrication-free) or…X (greasable) |

| When none of the above works, for example for motorsports and the aviation industry | “Motorsport” type…MTE (lubrication-free) |

Rod ends

Standard versions

RODOBALS’s standard series of rod ends and spherical bearings correspond to the standard according to DIN648K, Forms A and J, which means that the dimensions of the installation correspond to other makes available on the market with the same DIN standard. All dimensions in millimeters.

Shaft holes and threads

The inner ring shaft holes are lathed and polished with tolerance H7. Given dimensions of shaft holes are nominal and the base for size. For example, hole diameter 12 mm on rod ends is RF 12 and RM 12 with thread M12. Spherical bearing RG 12 and RS 12 have a shaft diameter of 12 mm and with different outer diameters.

Loads

The specified load values are referred to in Kilopond, Kp. The value represents the maximum static load limit before any permanent deformation of the body or bearing occurs.

Maximum dynamic load should not exceed 50% of maximum static load. For heavy static loads together with vibrations, 25% should not be exceeded.

Surface treatment

All RODOBAL’s (except stainless and stainless steel) are galvanized and chrome plated as corrosion protection. Before packing, all units are treated with heated anti-corrosion grease.

Lubrication

Initial lubrication and regular lubrication intervals are an important part, which protects against corrosion and wear, thus reducing the life span. Proper lubrication results in lower friction and thus increased life span. RODOBAL steel/bronze bearings must be initially lubricated with suitable grease after installation and before the first start.

Re-greasing interval depends on load, sliding velocity and type of motion. Designations which include the letter E (e.g., RF 10-SE, RM 12-AE) are lubrication-free and therefore should not be lubricated.

sign for lubrication-free design

Installation of spherical bearings

RODOBAL spherical bearings are an exclusive component that gives the best results and longest life span when installed correctly. Request information on recommended tolerances.

Three examples of RODOBAL and AURORA users.

F-RENAULT-Tatuus

Uses AURORA’s XAB-5T for critical places/strtuts, and RODOBAL RM… XE.CO for less critical.

The Renault F is almost as sophisticated and up front as an F3 car.

GLORIA-B10Y

Manufacturer of economic “singleseat”, for young drivers

Uses only RODOBAL type RM …- MTE, in sizes 8, 10, 12 and 14.12 (RM 14.12 MTE x1.5).

Their intention is to have rods with the maximum possible life span.

PICCHIO SRWC

Manufacturer of Sports Prototypes, track and hillclimbing cars

Uses RM…- MTE, sizes 8, 10 and 12.